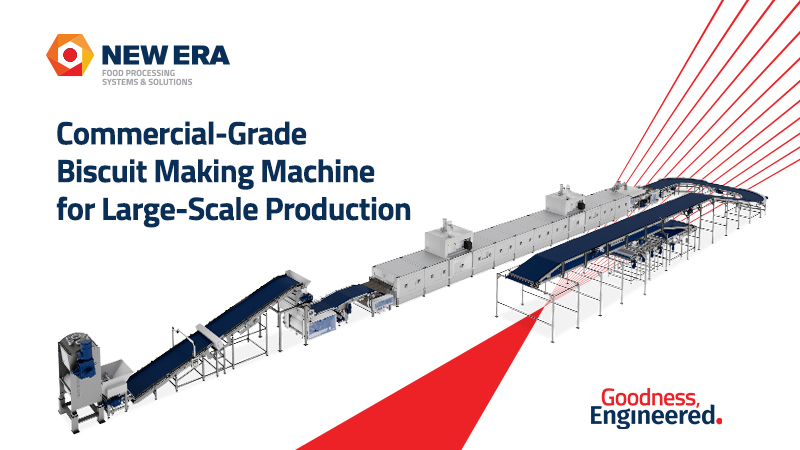

Biscuits are the most favoured bakery product consumed all over the world, be it for daily snacking or luxury indulgence. Increasing demands all over the world are putting manufacturers under pressure to produce more perfect biscuits, without sacrificing quality, consistency, and innovation. The keystone of this evolution is the Biscuit Production Line, a high-tech machinery system, intended to provide mass production of biscuits and cookies with automation and facilitation.

Be it multinational brands improving their production or local producers intending to expand, moving to commercial-grade production lines has become inevitable. They are not only efficient but also guarantee consistency in taste, aroma, and texture needed in the current competitive market.

Let’s examine the role of commercial-grade biscuit production lines and their exceptional benefits for large-scale manufacturers.

Why Large-Scale Manufacturers Need a Biscuit Production Line?

The expansion of biscuit manufacturing is much more than installing ovens and mixers. It must have smooth coordination between various processes like preparation and mixing of the dough, its shaping, baking, cooling, packaging, and more. The semi-automatic or manual system is likely to fall behind the demand, which results in non-uniformity and high operation costs.

A commercial-grade biscuit production line offers:

Unparalleled Consistency: Every biscuit is of the same size, thickness, appearance, and feels and looks exactly the same, passing the brand specifications for producing large batches.

High Output Levels: Automated lines have the ability to make thousands of biscuits (per hour) cutting down cycle time and increasing throughput.

Versatility: Depending on the production line, commercial production lines were manufactured in hard dough, soft dough, cookies or even a variety of bakery products.

Cost Efficiency: Less wastages, labor dependency and energy usage are optimised with these production lines; this reduces the cost of production.

Sustainability: The designs are energy efficient and have minimum wastage of raw materials (this completely conforms to the terms of environmentally friendly production).

Consumers are continuously upgrading to superior types of biscuits; therefore, such lines of production provide the manufacturers with an advantage to quickly respond to the changes and expand their business.

Key Components of a Biscuit Production Line

The contemporary production of biscuits is based on a simplified chain of manufacturing services, which are facilitated by sophisticated equipment. Part of the essence is:

Dough Mixing Units: This ensures that the right blending of ingredients is done in order to have a consistent quality of dough.

Forming Machines: Biscuits are formed depending on the type of dough by specialized equipment like rotary cutters, moulders, and wire cutters.

Baking Ovens: Baking ovens should either be a tunnel type or a hybrid type where controlled baking conditions allow the desired texture and flavor to be attained.

Cooling Conveyors: Avoid product moisture and make the product crisp.

Packaging System: Automated process provides speed, hygiene, and better presentation to make it retail-ready.

The combination of automation and intelligent surveillance makes every step of biscuit production under control and decreases the variability and human error.

Types of Biscuit Production Lines and Their Applications

Biscuits are not always made like one-size-should fit all. The biscuits are a snack that is immensely popular and the consumption habits towards the biscuits are varied. In 2024, the size of the biscuit market in the world was also USD 108.75 billion. The market is also expected to grow during the forecast period with an average growth of 5.70 per cent.

Therefore, the particular likes of the consumers and different dough recipes are worth knowing in order to produce the biscuits best.

#1 Hard Dough Biscuits

Hard dough biscuit varieties, such as crackers or cream biscuits, have to be cut into fine and equal thickness. Such products can be processed on rotary cutting lines, which provide them with a crisp texture and uniform shapes.

#2 Soft Dough Biscuits

Rotary moulding lines are used to make smooth, intricate shapes for smooth dough biscuits such as shortbread, butter biscuits, etc. Also, molded designs help ensure that they maintain soft textures.

#3 Cookies

Cookies require more flexibility since they come in different varieties that include chocolate chip as well as biscuits with fillings and deposits. Extruded and wire-cut lines make it possible to have a varied design that caters to innovative product development.

#4 Other Bakery Products

In addition to biscuits, sophisticated lines can be applicable to rusks, cakes, and other bakery products. The versatility allows large-scale manufacturing companies to gain flexibility in products without significant investment in different setups.

What Sets Commercial-Grade Production Lines Apart?

Commercial-grade systems, unlike small-scale setups, are designed to achieve industrial excellence, where precision, scale, and reliability are not optional. These lines are not mere automatic lines but are capable of providing a strong end-to-end solution, keeping in line with what large-scale businesses want.

Throughput Efficiency: The capacity to have a constant high volume of production so that it can serve the domestic and international supply chains adequately without necessarily changing the production quality.

Digital Integration: IoT-based monitoring systems and PLC controls let you acquire real-time information and minimize the risk of downtime.

Customisation Capabilities: The bespoke designs can be customised to countless recipes, product dimensions, and packaging formats, which grants the manufacturers more flexibility in the market.

Compliance: Designed in accordance to meet the stringent hygiene and food safety norms, so that there is easy entry into markets abroad.

Scalability: Modular systems help producers quickly scale to extend their product lines and increase output, when necessary.

Conclusion

The future of the biscuit industry lies in efficiency, flexibility, and scalability. A commercial-level Biscuit Production Line will allow manufacturers to place themselves ahead of demand and deliver uniformity and innovation when it comes to quality. From dough to cookies and other bakery products can now be manufactured with automated systems, extending industrial dependability and precision to each process in small to large volumes.

The right biscuit production line manufacturers, like New Era, are the ones to partner with to achieve long-term success. We are experts helping brands go beyond mere production to mass production with perfection. Our production lines are not only a smart choice but a necessity, especially for manufacturers with growth prospects in the competitive business environment.

Ready to Scale Your Biscuit Production? Contact now!

FAQs

1. What is a Biscuit Production Line?

A biscuit Production Line is more or less an automated process to bake biscuits and other bakery goods in large quantities and of top-quality and performance.

2. Is it possible to manufacture various kinds of biscuits by a single production line?

Yes, modern lines can be customized in order to make hard and soft dough in the form of cookies and other bakery products, having quick changeover capabilities.

3. Why should large-scale biscuit manufacturers invest in automated biscuit lines?

There is some sense of consistency; the cost of labor is minimized, errors are reduced, and output is increased to respond to the rising consumer demand through automation.

4. What should I look for to select the appropriate Biscuit Production Line Manufacturer?

Seek manufacturers that not only have the proven expertise, have a wide product range, give you after-sales support, and are also able to modify solutions to your specifications, like New Era.