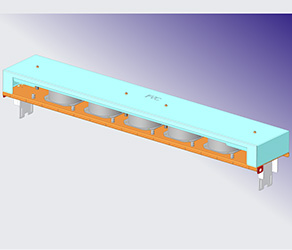

Mixing Systems

High-speed mixers can be used for a wide range of doughs, including hard biscuits. It can also be effectively used for creaming applications. The modular dough processing equipment can be customized to perform suitably for different needs and specifications.