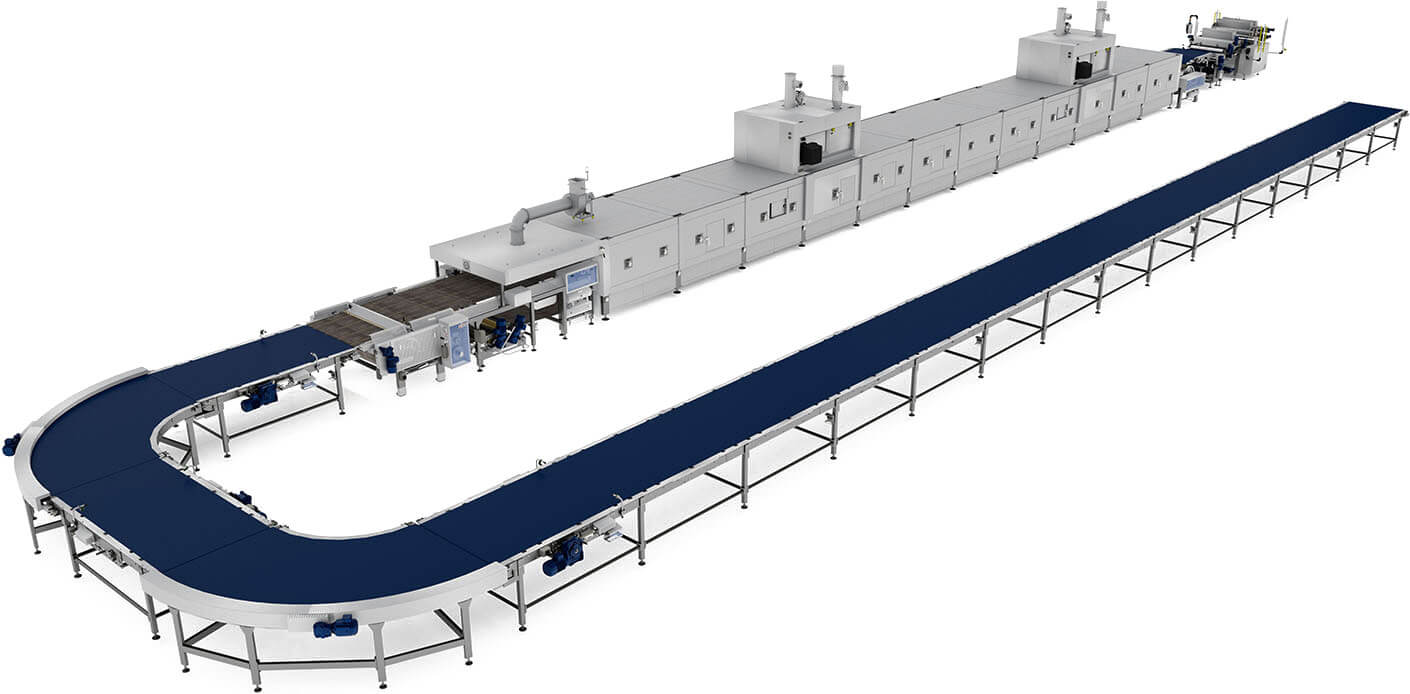

Mixing Systems

The all-inclusive mixing system is designed with utmost precision. The mixer can be used for different types of products, without compromising on its performance. These mixers can be easily integrated with multiple production lines ranging from cookie production lines to other bakery & biscuit lines.