Hard Dough Biscuits & Crackers Production Line

Hard dough biscuits and crackers are crisp, low-fat snacks made from fermented dough that is sheeted, laminated, and cut before baking. Popular products include Marie biscuits, cream crackers, Petit Beurre to name a few variants. These biscuits are known for their light texture, long shelf life, and wide market appeal. At New Era, we offer fully automatic lines designed for precision sheeting, consistent baking, and hygienic operation.

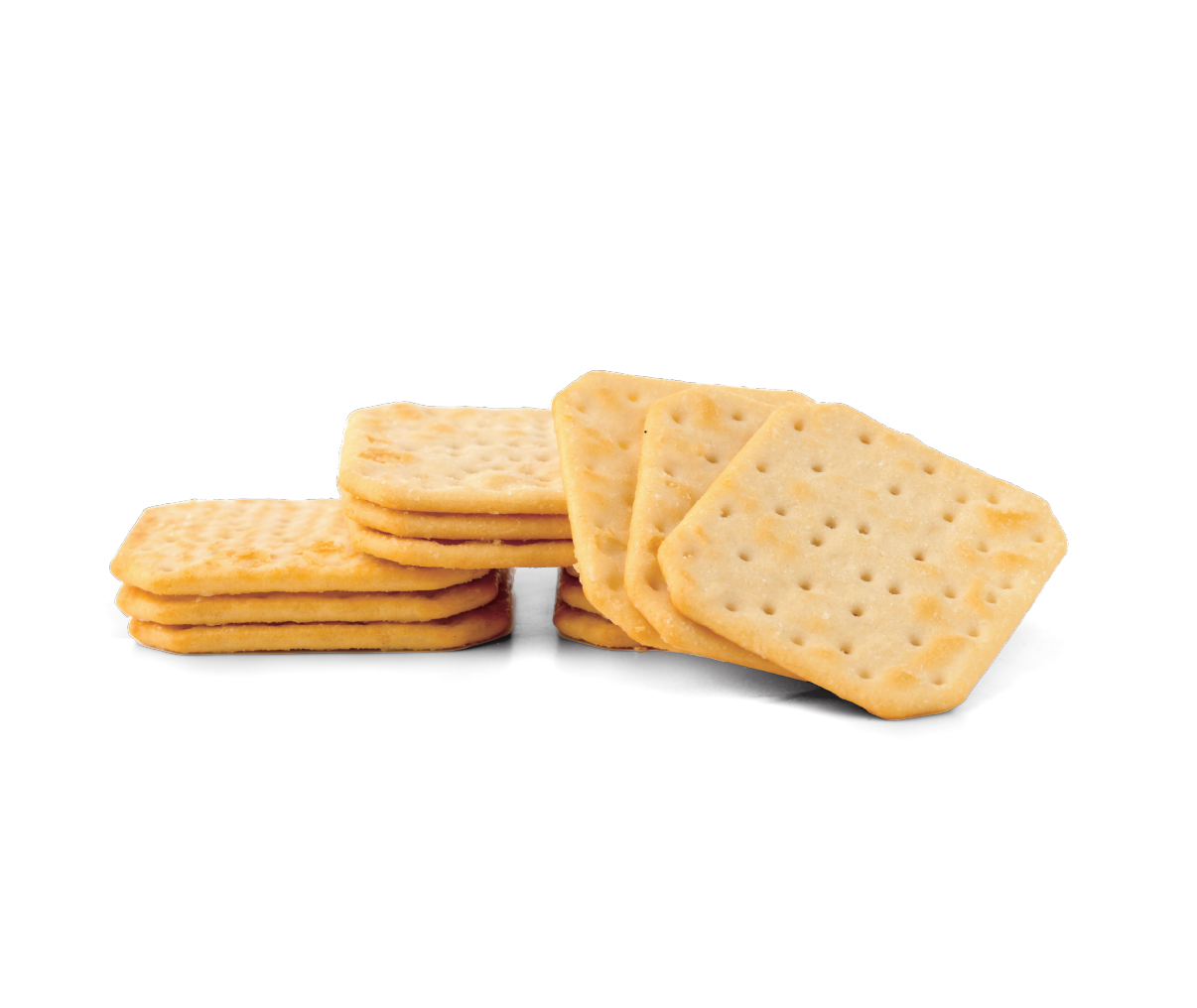

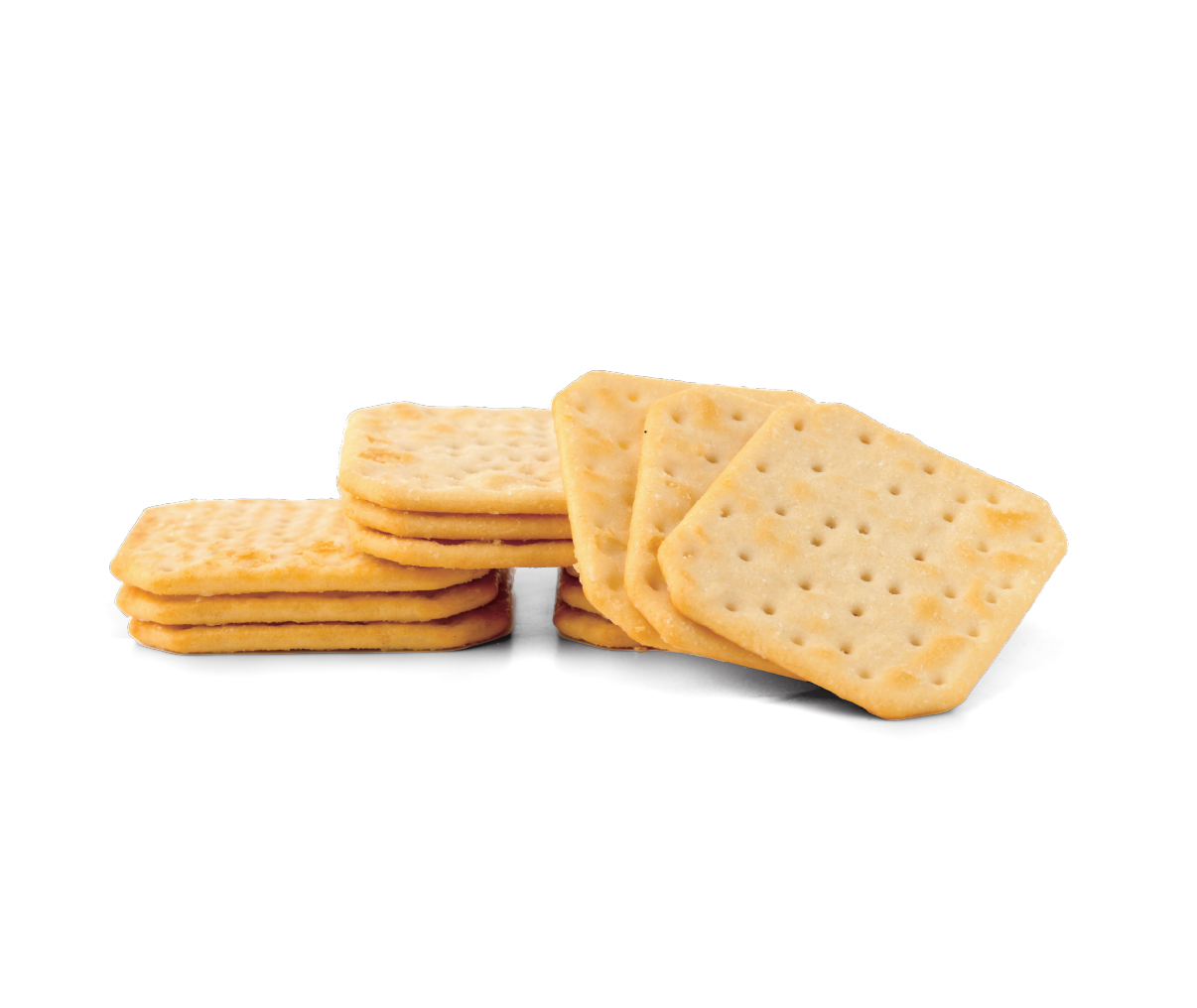

Cocktail Crackers

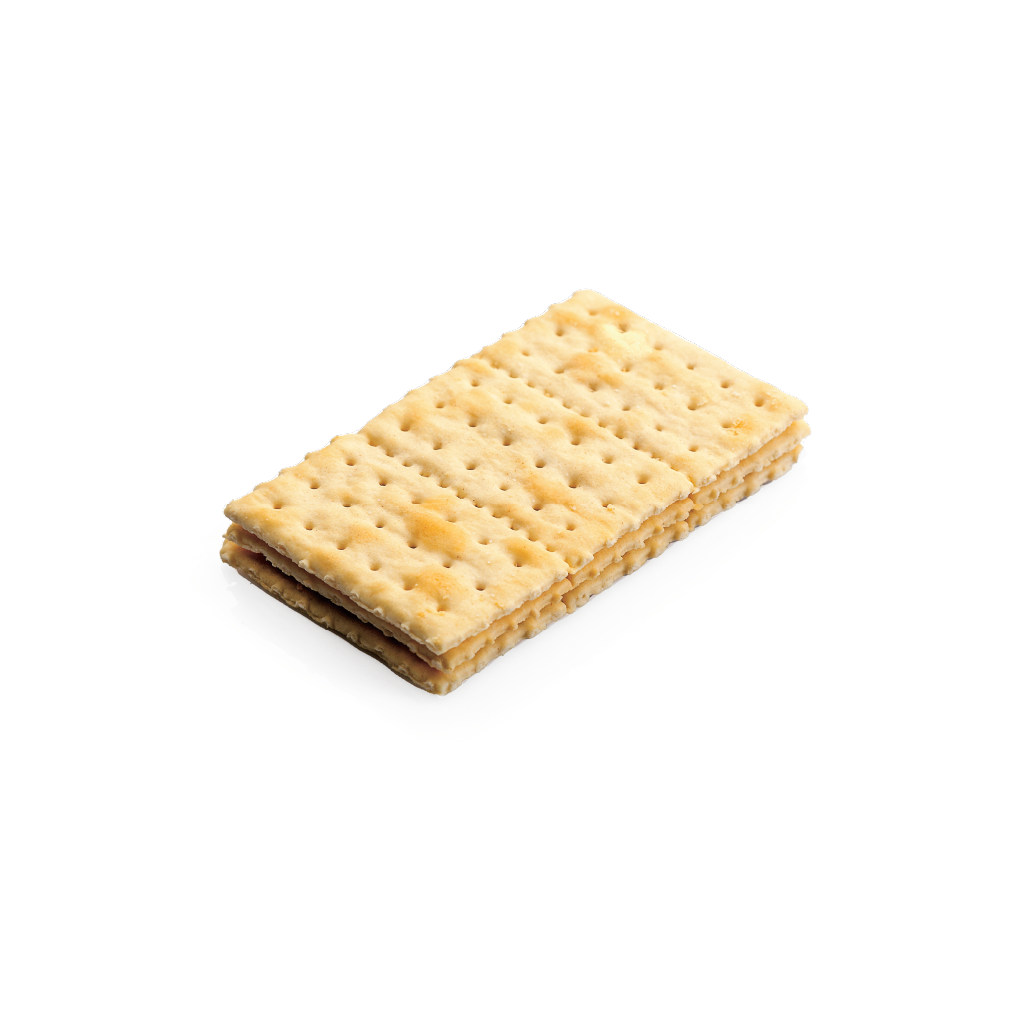

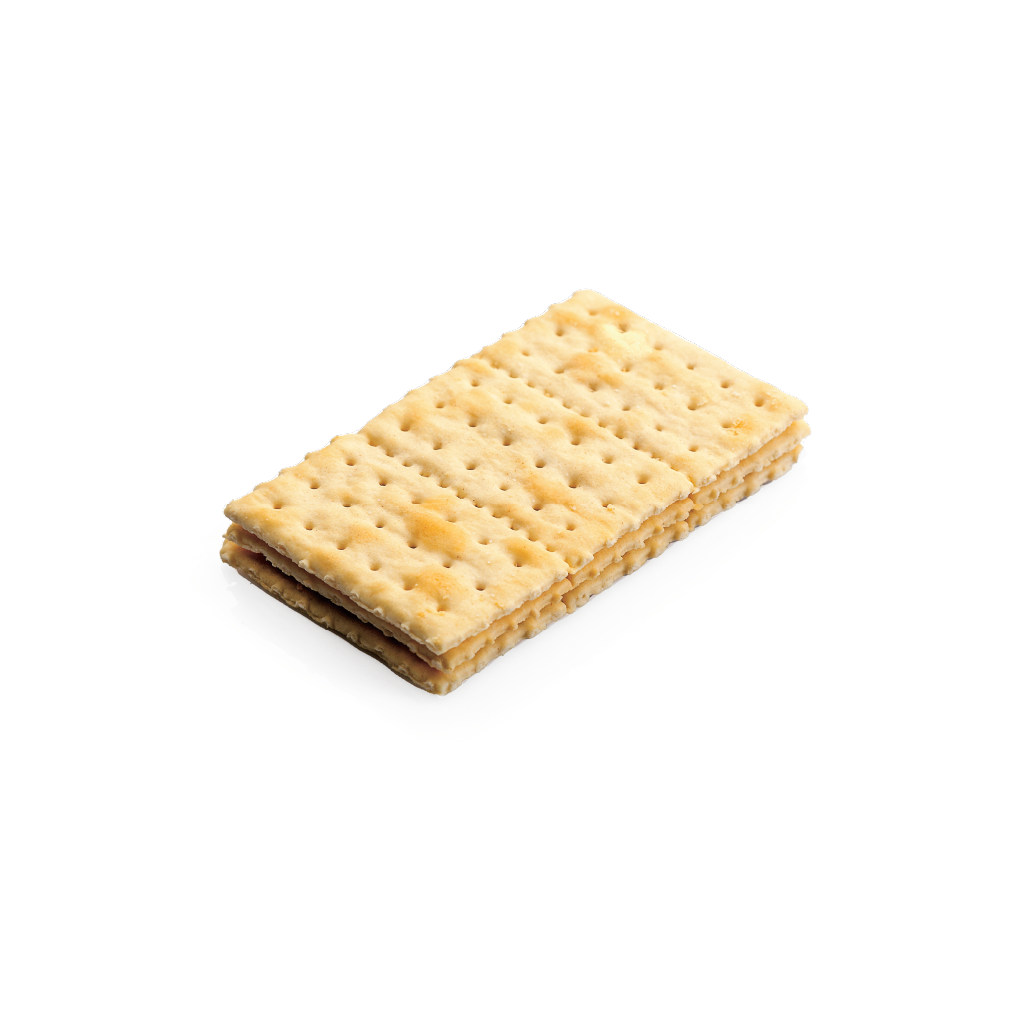

Malkist Sandwich Crackers

Sugar Glazed Biscuits

Pettit Beurre

Salty Pretzel

Cream Crackers With Herbs

Chocolate Injected Biscuits

TUC Crackers

Potato Crackers

Soda Crackers

Marie Biscuits

Sugar Glazed Cream Crackers

Cocktail Crackers

Malkist Sandwich Crackers

Sugar Glazed Biscuits

Pettit Beurre

Salty Pretzel

Cream Crackers With Herbs

Chocolate Injected Biscuits

Tuc Crackers

Potato Crackers

Soda Crackers

Marie Biscuits

Sugar Glazed Cream Crackers

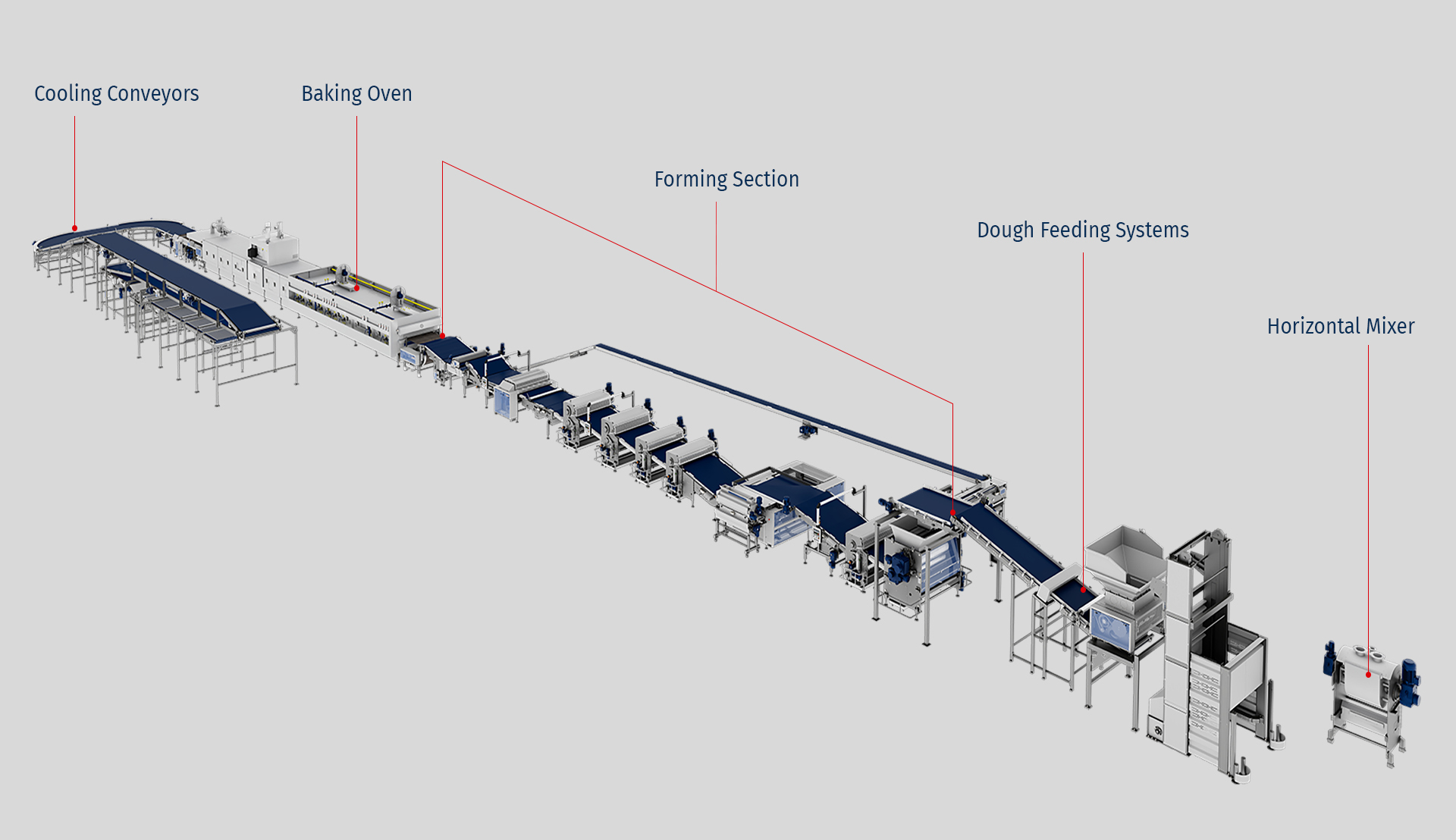

Rotary Cutting Line For Hard Dough Biscuits & Crackers

Mixing

Systems

The Horizontal Mixer is designed for efficient and uniform mixing of wide range of doughs used in biscuit and cracker production. Its robust construction and powerful Z Arm blade mixing system ensure thorough blending of ingredients, resulting in consistent dough quality batch after batch. Ideal for medium to large-scale operations, the mixer features a tilting for easy dough discharge and reduced handling time.

Precision controls ensure accurate mixing time and dough temperature. Built with food-grade materials and hygienic design, the horizontal mixer offers reliability, ease of maintenance, and seamless integration into automated production lines.

Key Highlights

Feeding

Systems

The Dough Feeding System ensures continuous, hygienic, and efficient transfer of mixed dough from the horizontal mixer to the processing line. Designed for consistent flow and minimal dough damage, it uses a combination of conveyors, hoppers, metal detection process and automatic rejection depending on the application and dough type. The system reduces manual handling, improves process efficiency, and maintains dough integrity throughout.

Built with highest standards, it is easy to clean and integrates seamlessly with automated lines. Ideal for wide range of doughs, the feeding system helps maintain line rhythm and uniform product quality.

Key Highlights

Forming

Systems

The forming process transforms the dough into unique shapes and seamlessly transfers the shaped biscuits to the baking systems. New Era’s forming systems combine flexibility with advanced engineering. Our engineering minds have designed & developed systems that meet a diverse types of project requirements. Whether you need a sheeting line, a lamination line for hard biscuits or crackers, or a short footprint sheeting line, we provide them all.

Key Highlights

Baking

Systems

Our ovens are engineered to deliver accurate heat control, uniform baking, and energy efficiency. Depending on your product profile, you can choose from:

Key Highlights

Post Baking

Systems

Our post-baking solutions ensure a smooth transition from oven to packaging, with a strong focus on hygiene, flow control, and process optimization. From cooling and stacking to sandwiching and integrated packing lines, we enable you to maintain product integrity and maximize throughput