Cookies Production Line

From wirecut to deposited and co-extruded cookies, our lines are designed to handle a wide variety of dough with or without inclusions and fillings. Whether you’re scaling a classic recipe or launching a new SKU, our systems support creativity and operational efficiency.

Cocunut Biscuits

Twin Coloured Biscuits

Deposited Biscuits

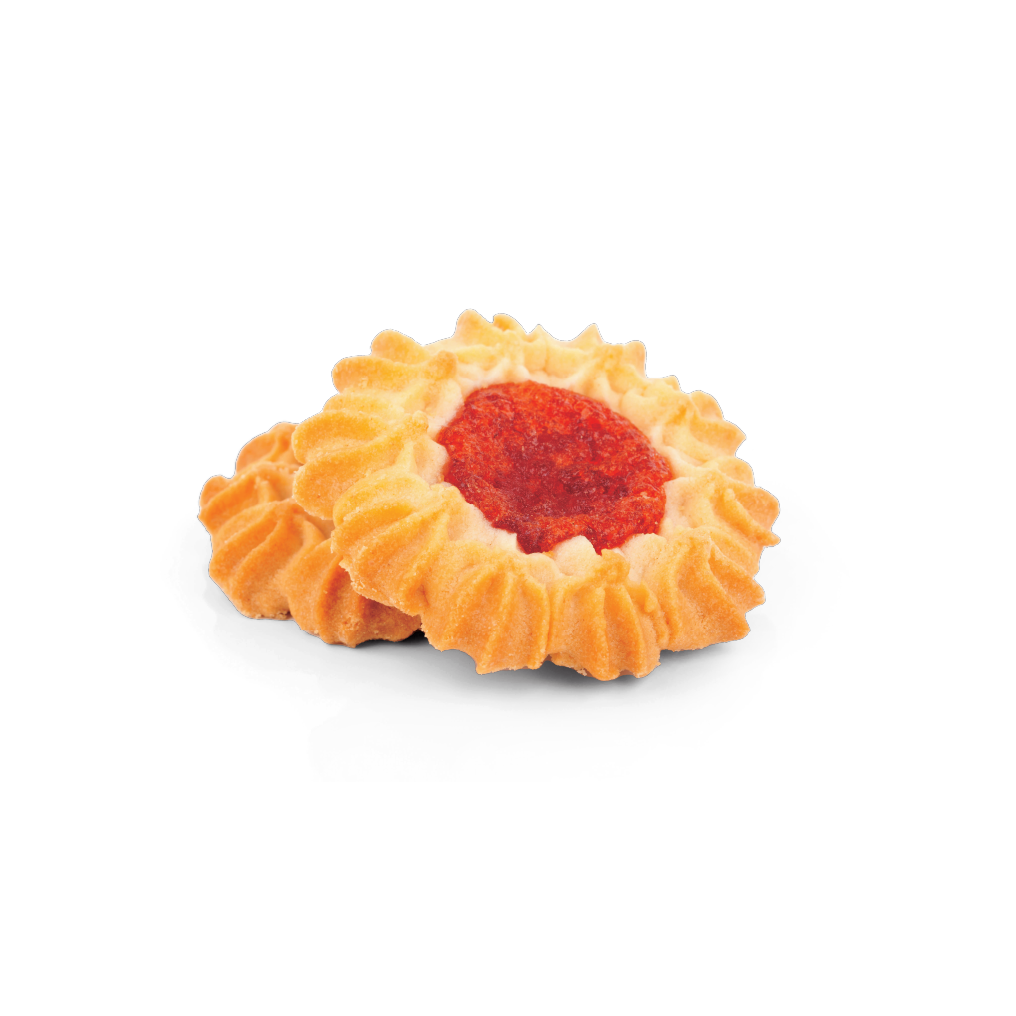

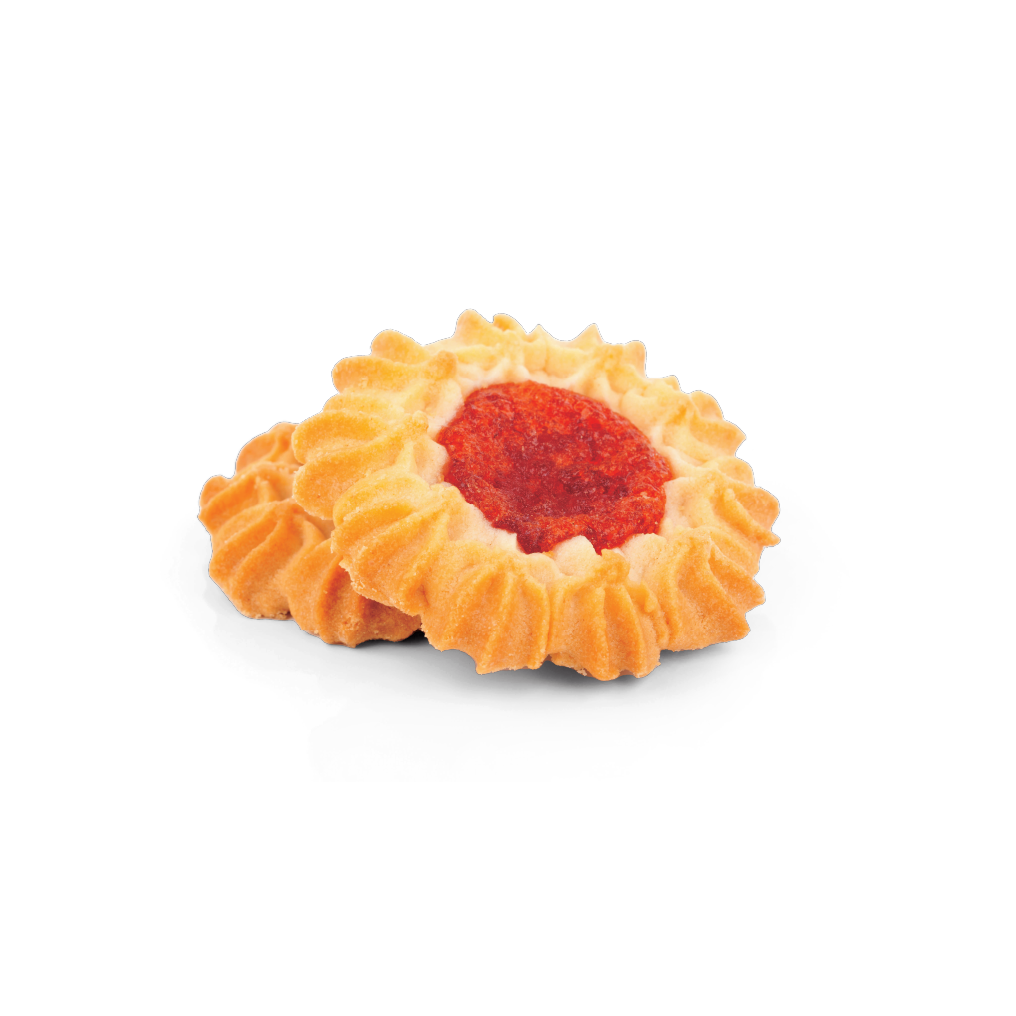

Jam Filled Cookies

Choco-Pie Sandwich

Date Filled Cookies

Butter Cookies

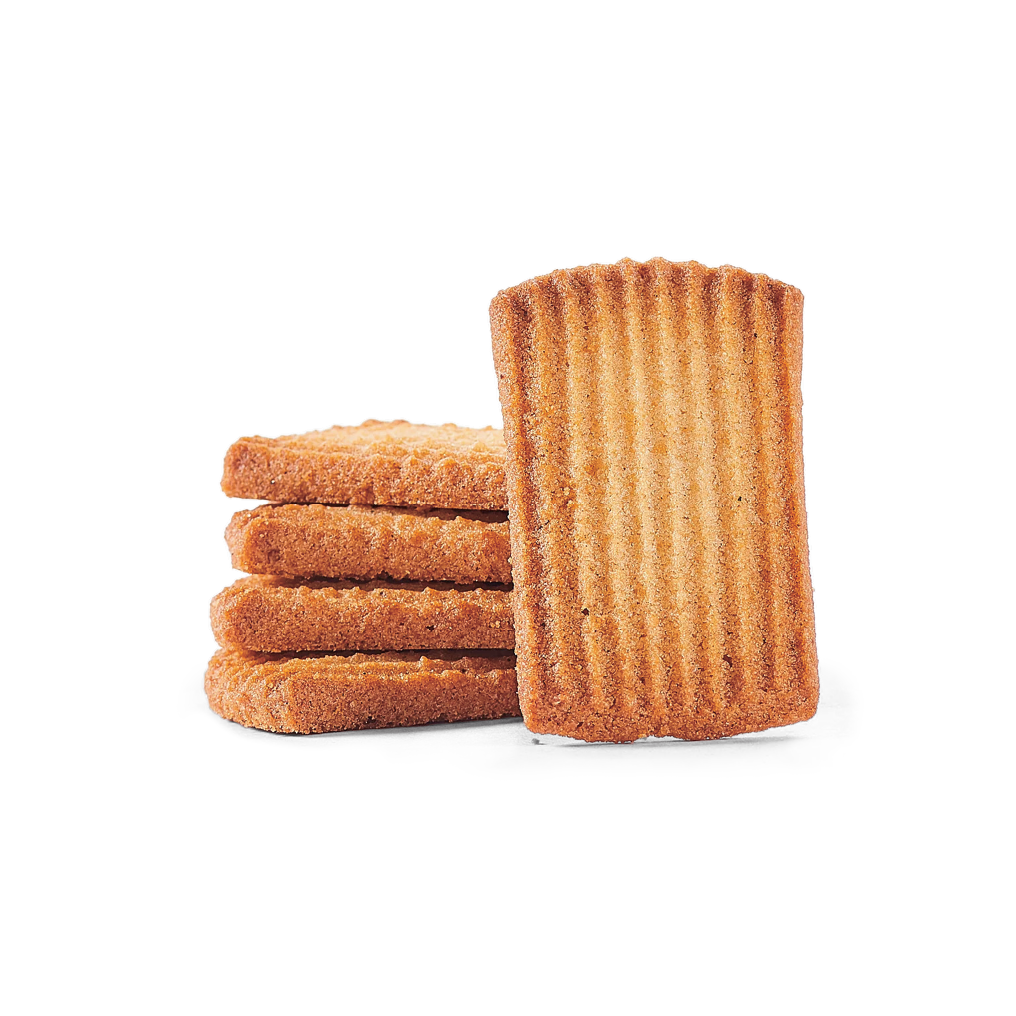

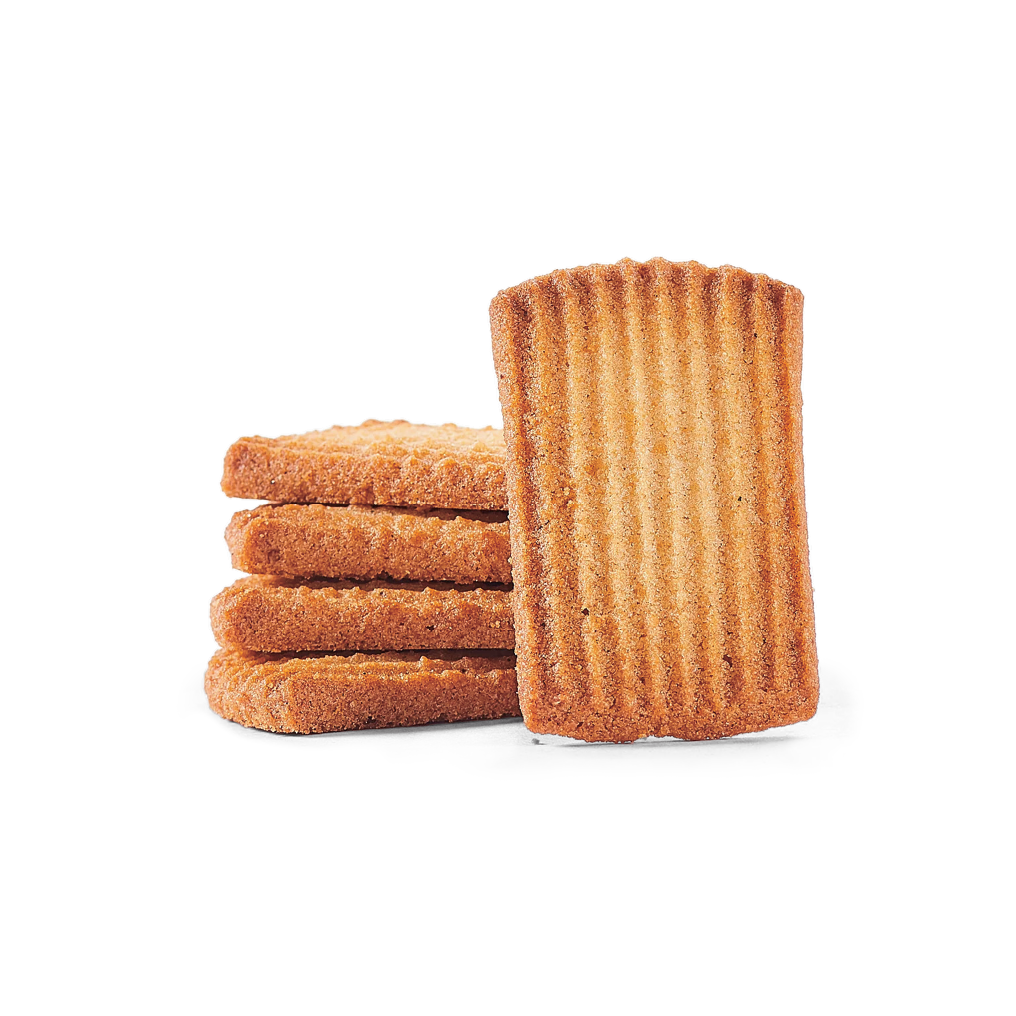

Atta-Cookies

Center Filled Cookies

Choco Chip Cookies

Danish Cookies

Coconut Biscuits

Twin Coloured Biscuits

Deposited Biscuits

Jam Filled Cookies

Choco-Pie Sandwich

Date Filled Cookies

Butter Cookies

Atta-Cookies

Center Filled Cookies

Choco Chip Cookies

Danish Cookies

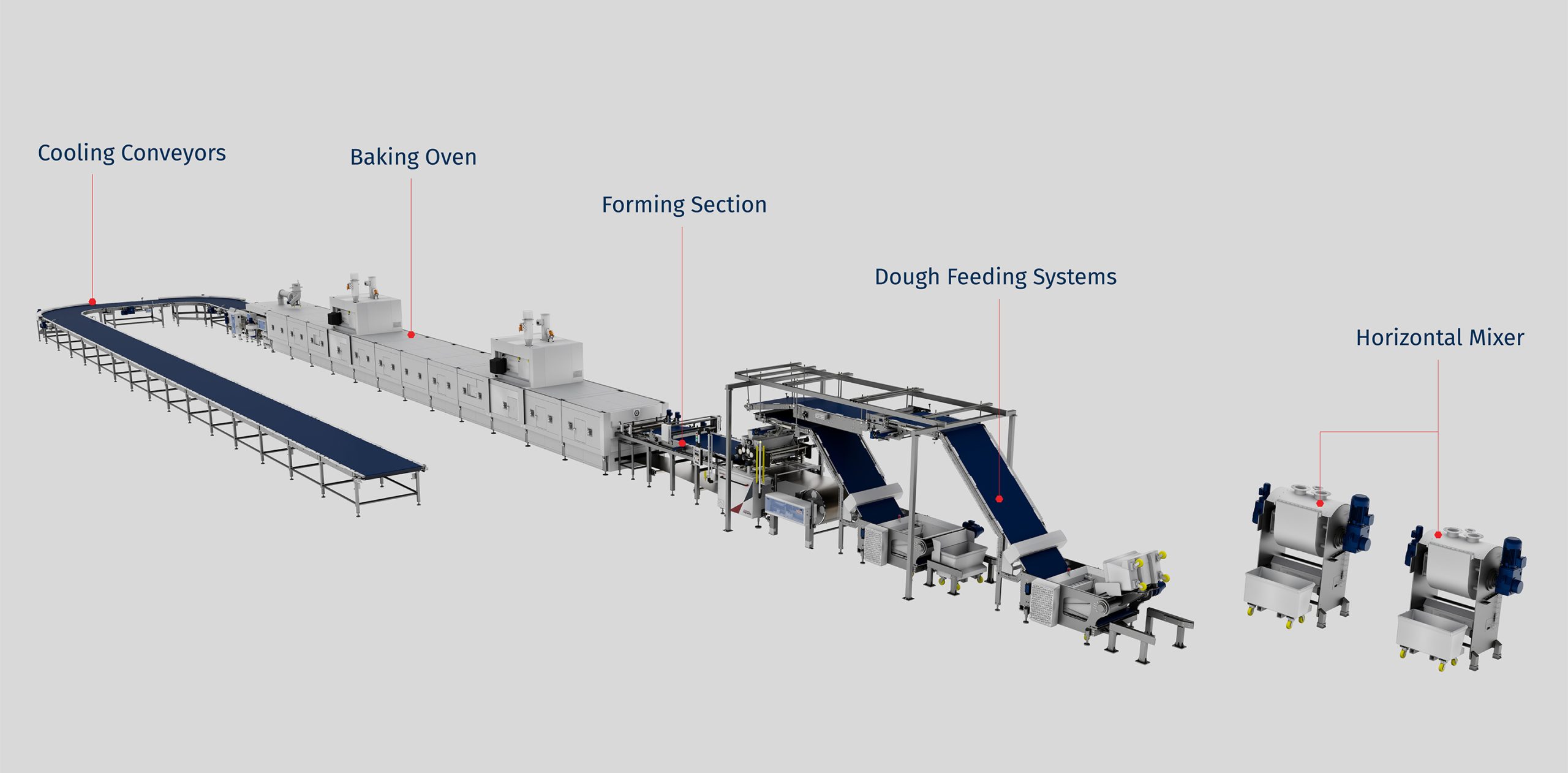

Wire-Cut/ Deposited/ Extruded Products Line

Mixing

Systems

The Horizontal Mixer is designed for efficient and uniform mixing of wide range of doughs used in biscuit and cracker production. Its robust construction and powerful Z Arm blade mixing system ensure thorough blending of ingredients, resulting in consistent dough quality batch after batch. Ideal for medium to large-scale operations, the mixer features a tilting for easy dough discharge and reduced handling time.

Precision controls ensure accurate mixing time and dough temperature. Built with food-grade materials and hygienic design, the horizontal mixer offers reliability, ease of maintenance, and seamless integration into automated production lines.

Key Highlights

Feeding

Systems

New Era offer standard feeding systems to suit your varied doughs. The system includes metal detection to assure the dough is free of any metal contamination. Armed with the latest features like automatic dough detection & rejection & precise dough distribution, it makes a promising case of delivering high-quality cookies & other biscuit batches consistently.

Key Highlights

Forming

Systems

Wire-cut, depositor, and extruder are designed for forming soft, high-fat doughs and batters into uniform shapes directly onto oven band. Ideal for cookies, center-filled biscuits, Twin Colored cookies, these machines offer precision accuracy, high-speed performance, and flexibility in product variety.

- Wire-Cut Machines create cookies with distinct shapes using a wire blade.

- Depositors handles semi-liquid or soft doughs for drop cookies.

- Extruders produce consistent bars sticks, and are then cut to desired length.

New Era Machines offers fully automated solutions with servo-controlled operation, easy recipe changeovers, and hygienic, stainless-steel construction for seamless integration and cleaning.

Key Highlights

Baking

Systems

Baking, one of the most crucial stages, where the product takes the final taste and texture, requires efficient baking systems. A wide range of high-quality baking ovens with superior features like low fuel consumption, uniform heating & ambient temperature control makes sure you get the best product like delicious cookies every time.

Key Highlights

Post Baking

Systems

Our post-baking solutions ensure a smooth transition from oven to packaging, with a strong focus on hygiene, flow control, and process optimization. From cooling and stacking to sandwiching and integrated packing lines, we enable you to maintain product integrity and maximize throughput